Cyanone

Project Brief

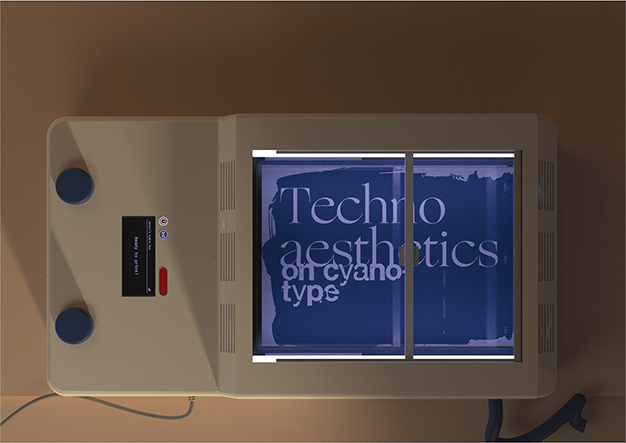

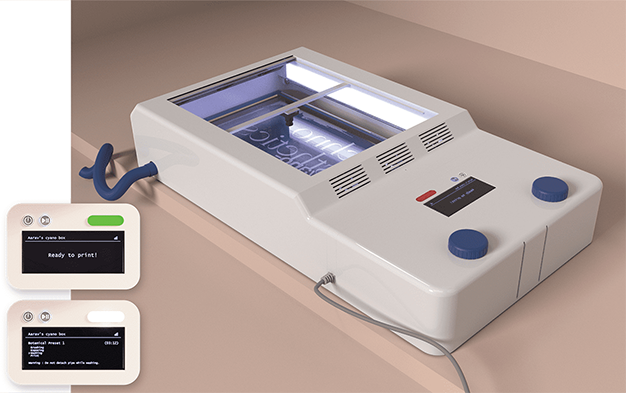

Designing a user centric product which converts manual printing process to a functional printer. The user-friendly printer keeps the fascinating part of the process alive by providing varied operational features and options. The industrial part of project was done in a team of 3, later I carried it forward to develop application that connects to the product.

| Role | Product designer/ Conceptualisation/ Prototyping |

| Timeline | 1.5 Month |

| Skills | User Research, Product Design, Interaction Design, Visual Design, UX Design, Concept Development |

| Tools | Figma, Keyshot, Rhino 3D, Fusion 360, Adobe Suite |

Did You Know?

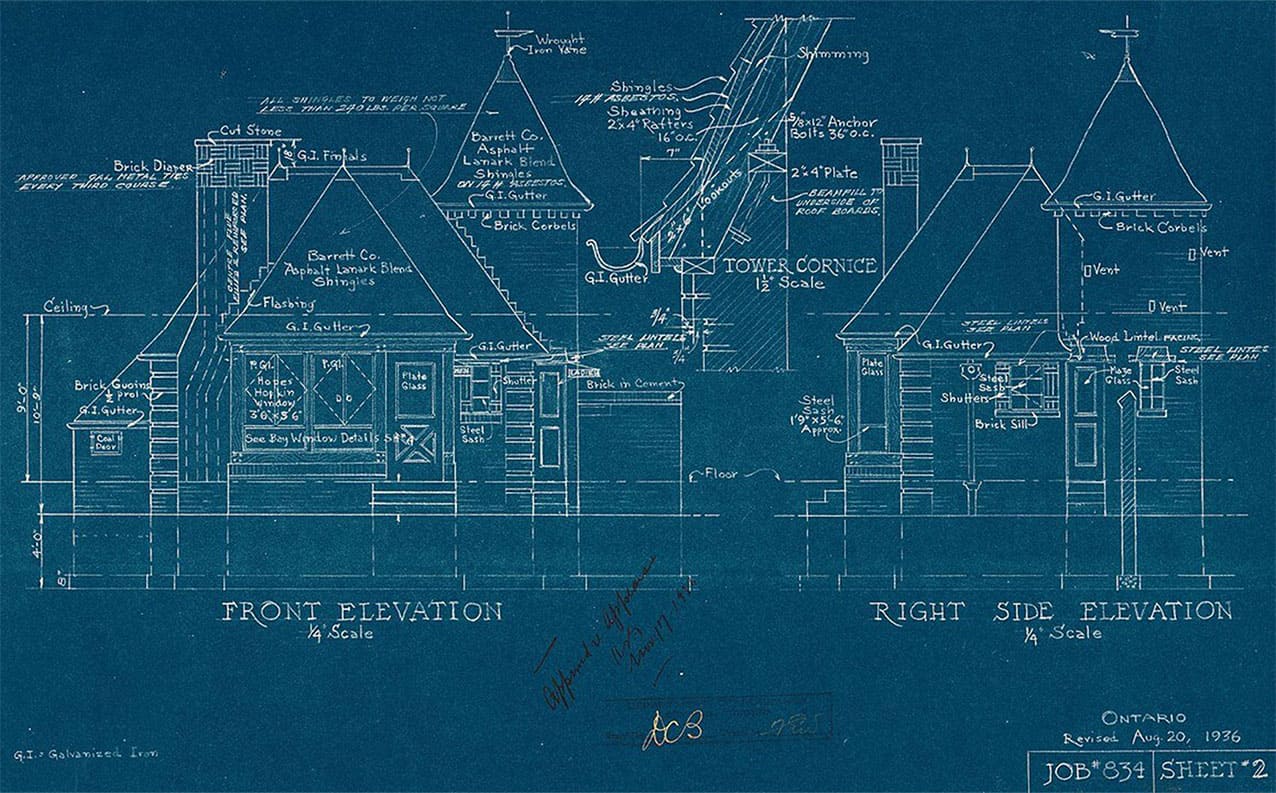

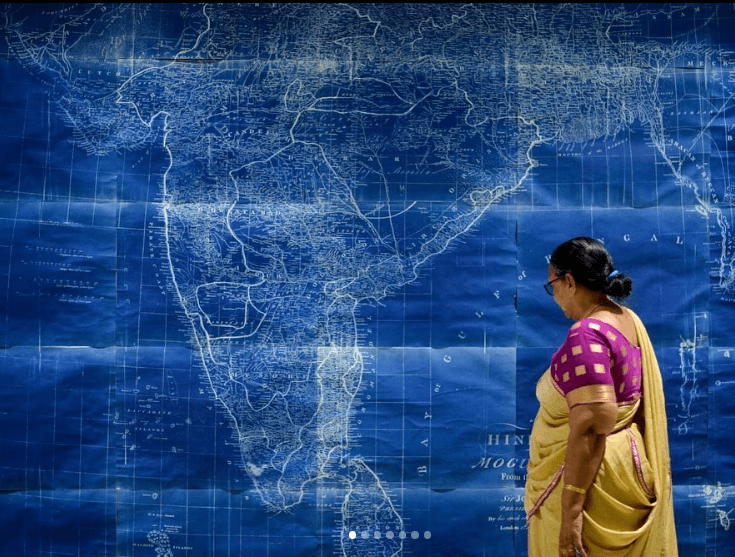

The term "blueprint" comes from the use of cyanotypes.

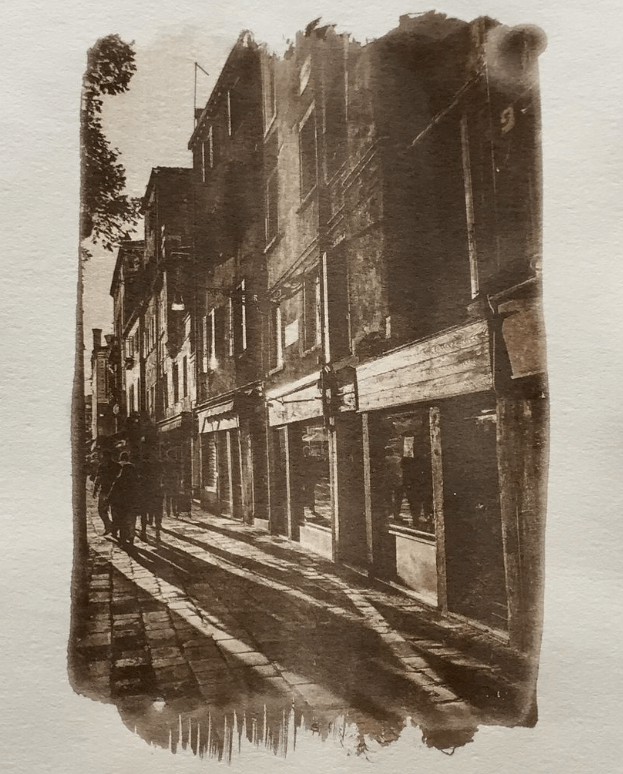

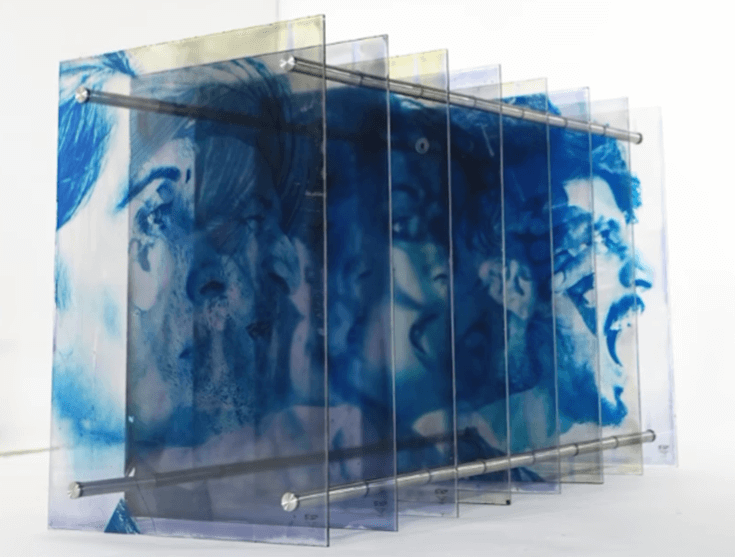

- Cyanotype is a manual printing process, historically used by architects to present blueprints of their project plans.

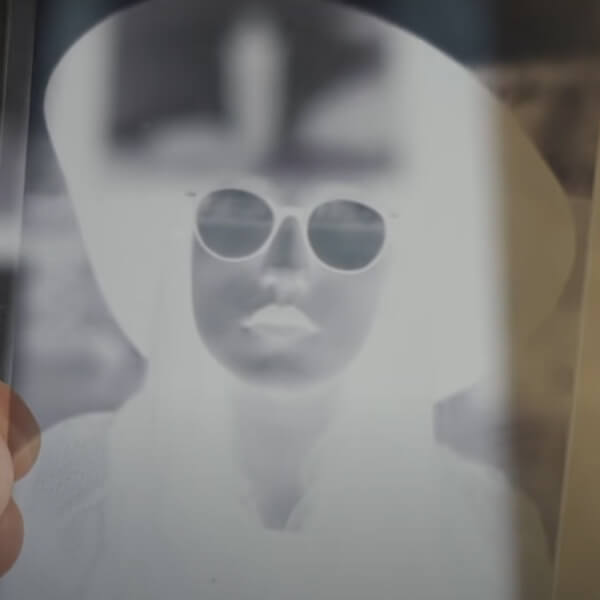

- It is majorly used by Artists, Photographers & Designers by mixing chemicals and naturally producing print.

Things Needed

Chemicals

Dropper/Measuring Cup

Paint brush/Foam brush

Developing tray

Paper

Negative print/Article

Glass & Base/Frame

Sunlight

UV Lamp

Manual Process

Steps of traditionally developing cyanotype print.

Measure & mix the chemicals in a dark place

Paint the paper & leave to dry

Place the negative in the frame

Place the dried painted paper on top of it

Close it such that it is properly pressed

Place it under UV light/ sunlight to expose it

Remove the paper from the frame

Wash the paper in the developing tray

Leave to dry out completely

Print is ready

Interviews

Interviewed experts in the industry to better understand the process.

JILL ENFIELD

| AGE: | 66 Years |

| GENDER: | Female |

| EDUCATION: | New York University Visual Studies Workshop |

| LIVES: | New York |

| OCCUPATION: | Photographer & Hand Coloring Artist, Tutor at Parsons The New School for Design, Fashion Institute of Photography, New York University, Long Island University, Brooklyn Campus, and the International Center of Photography in New York City as well as RISD. |

| WOW: | the color and you can change the color by toning by using different toners which are organic like tea, coffee. |

| CRITICAL: | spillIng of chemicals which stain everything and spoils everything |

SIDDHARTH KANERIA

| AGE: | 35 Years |

| GENDER: | Male |

| EDUCATION: | National School Of Interior Design |

| Lives: | Rajkot |

| OCCUPATION: | Photographer & Tutor of alternative Photography |

| Works: | Pinhole Camera of Life size, Exhibitions at prestigious Galleries |

| SUGGESTIONS FOR THE PRODUCT: | At least make a blackbox for UV light exposing with timer control Take inspiration from UV scanners used by architect before the invention of printers It should not lose the artist’s freedom of experimentation due to the device. |

| WOW: | Seeing the print turn blue while washing it |

| CRITICAL: | Chemistry part of the process |

| TEDIOUS: | Exposing time |

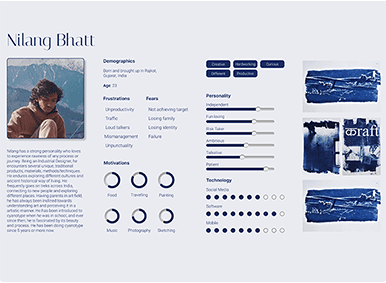

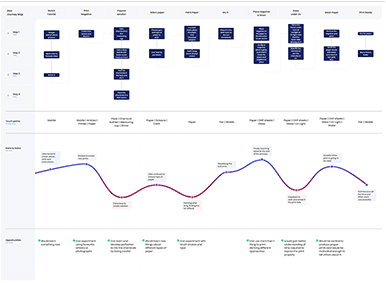

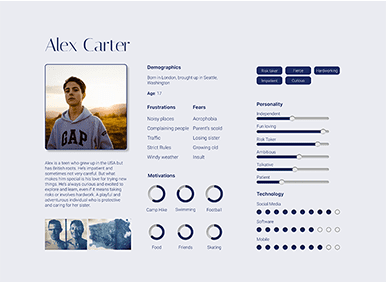

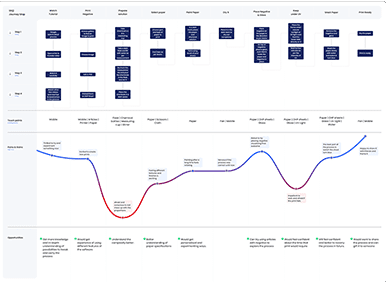

PERSONA AND JOURNEY MAPPING

To understand users, created personas and journey mapping for 3 characters, 1 is doing the process again,

2 are doing the process for the first time in which 1 fails and other succeeds.

INSIGHTS

Derived from interviews & primary research, persona and journey mapping study

- The most amazing factor of the process is washing the print.

- Chemistry part of the process is critical. The chemicals need to be mixed proportionately.

- People are aware but have not practiced it yet.

- They want to carry out the process for fun and experimentation rather than commercial/utility purposes.

- Most people love the process because of the artistic touch involved in it over common printing technologies. The product should be augmented rather than replaced.

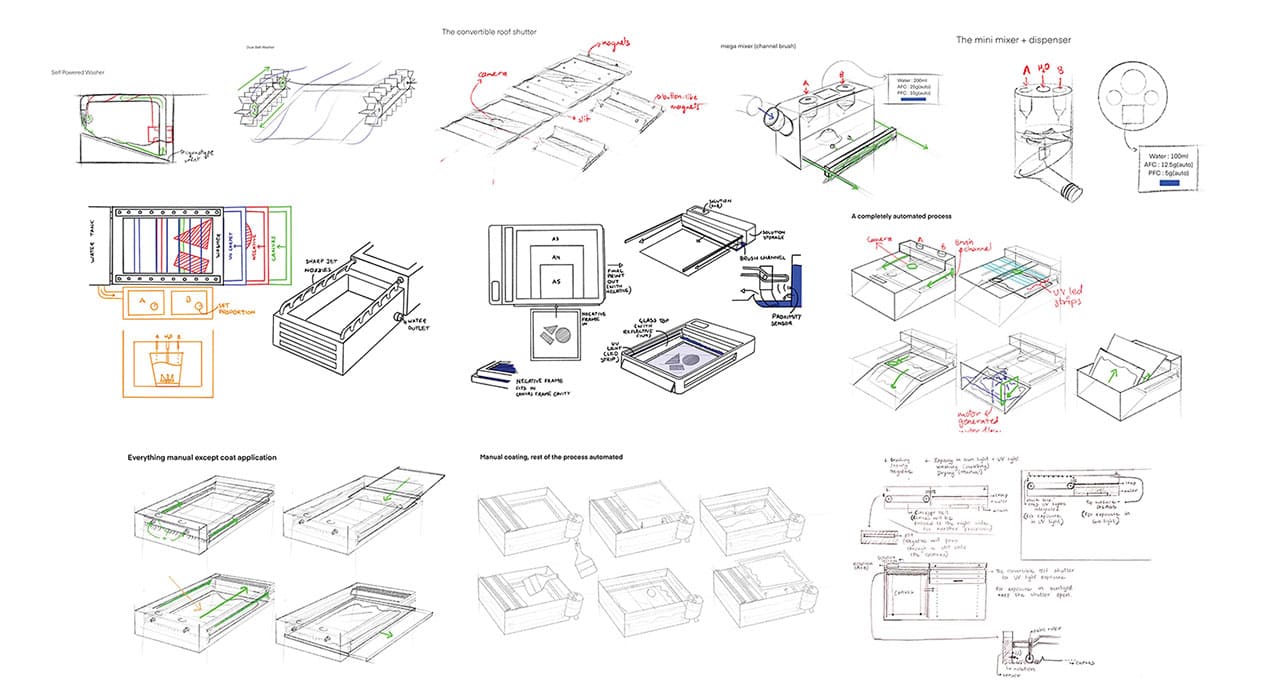

IDEATION

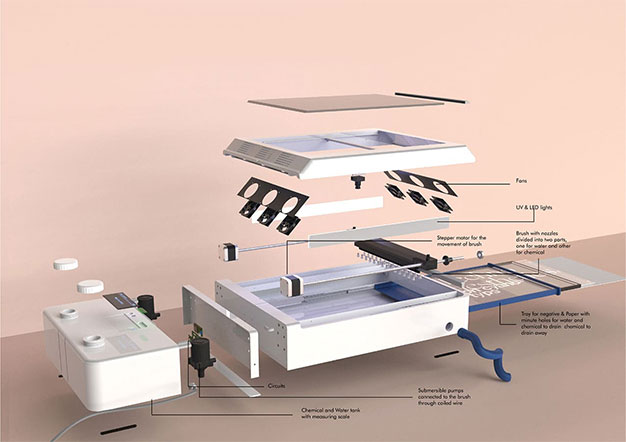

PRODUCT DEVELOPMENT

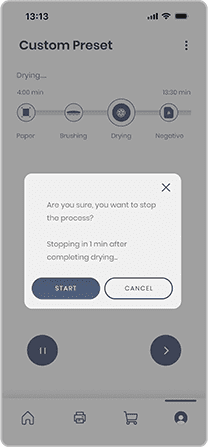

The product involves submersible pumps to pump the water and chemical to the brush when commanded. The panel of fans increases the rate of drying the print, 2 stepper motors placed on both ends define the movement of the brush. The brush has 2 separate cavities and a set of nozzles for water and chemical each. The UV lights can be adjusted as per the intensity specified.

The LED strips create basic illumination in the printer that can be enjoyed by the user from the glass top without hindering chemical sensitivity. A Wide angle camera is attached to the top of the canvas tray, it monitors the print while creating videos and photos for the user. The water would drain off from the holes created on the tray through the drainage pipe. The circuits are smart places such that the area doesn't come in contact with water as well as the assembly could easily be repaired in future.

The product attempts to automate most steps while keeping a few steps optional. The brushing is a step where artists would love to stroke on a canvas. The product allows choosing between the manual or automated brushing.

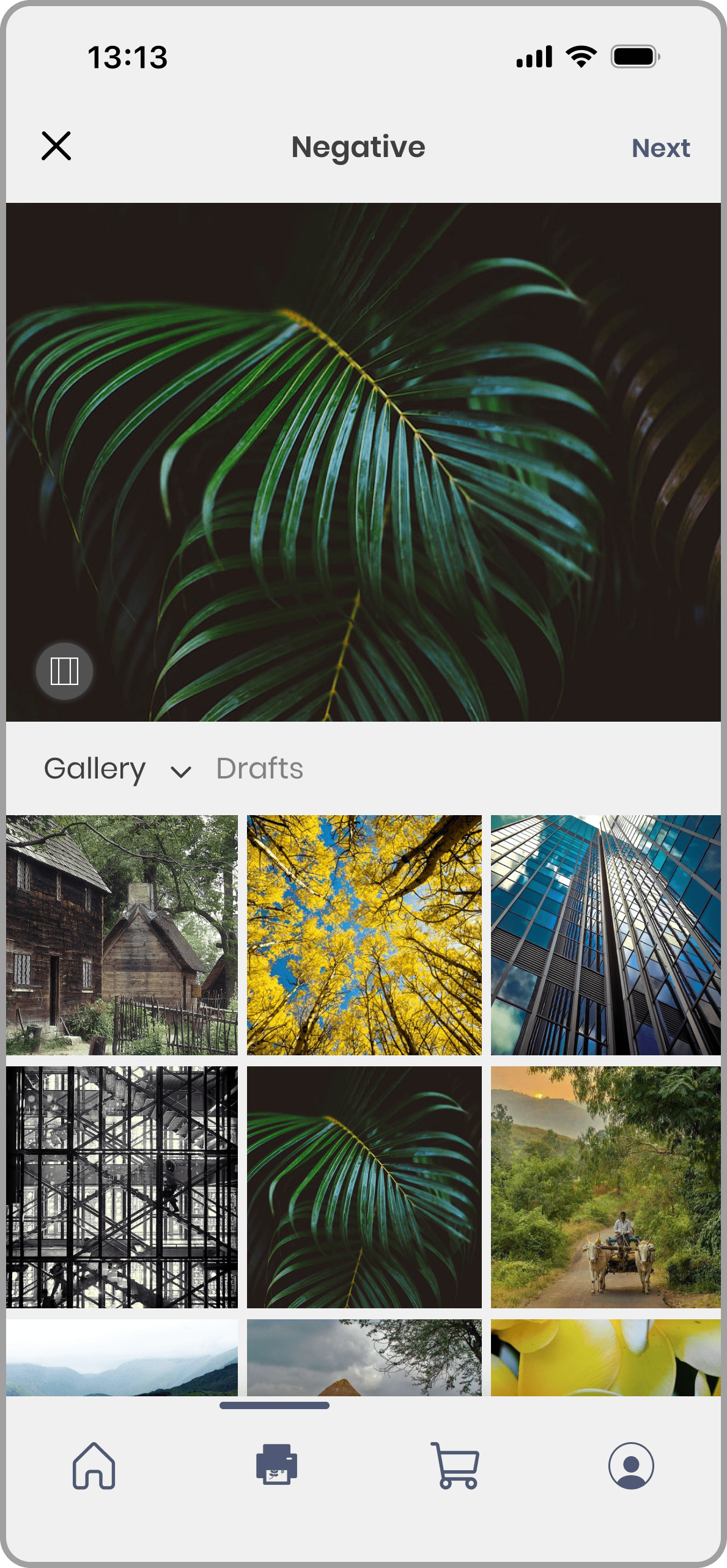

For different gradients of colour, the chemical could be altered as per the user's preferences. The product is operated by an app that allows choosing the specifications. Since the process is experimental, it allows making a few customisations while keeping a check of the process, letting users to sit back and enjoy while their print is getting ready!

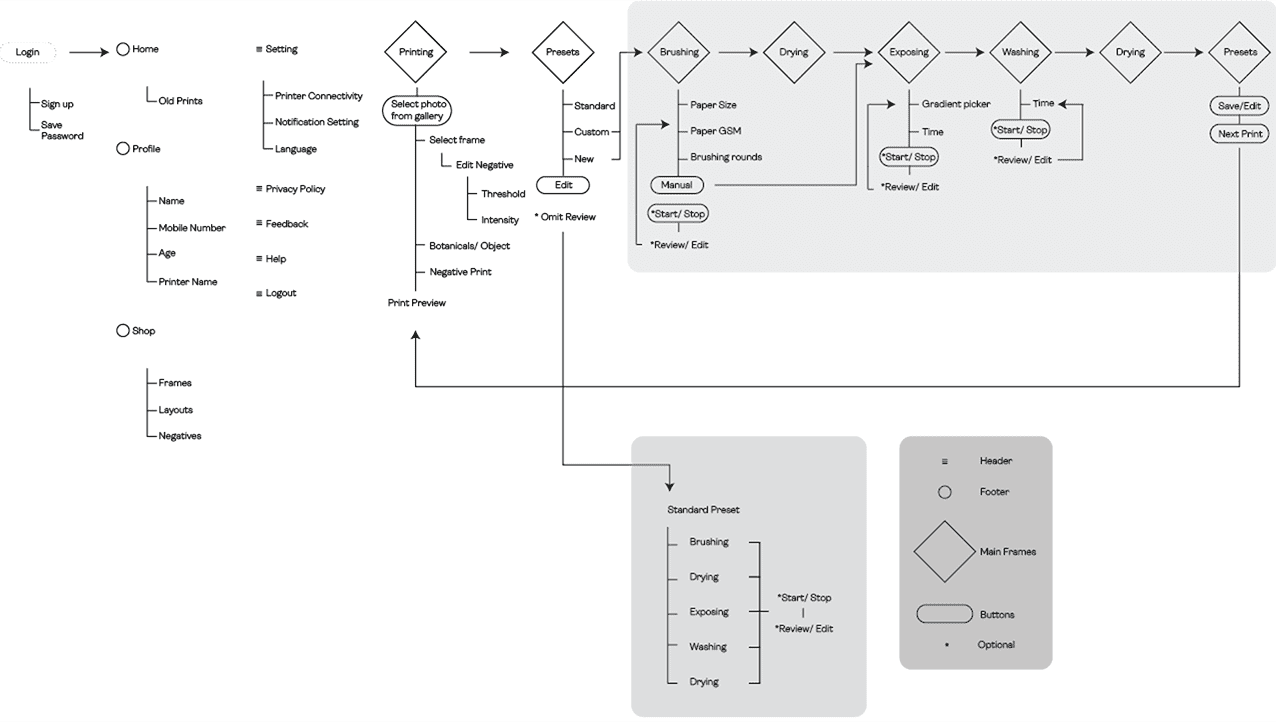

INFORMATION ARCHITECTURE

Designed to coordinate with product, dividing the process in a way that a new user can easily navigate.

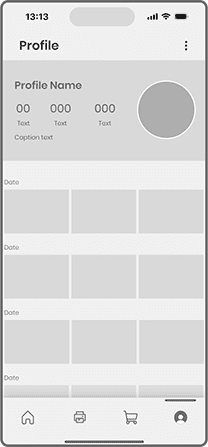

Users can save their print features to repeat it in future.

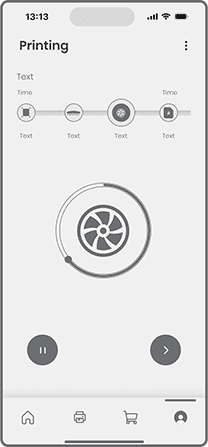

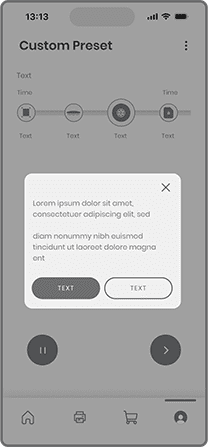

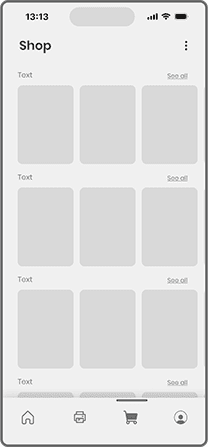

Wireframes

The app is designed with intricate detailing in the wireframes. The design attempts to include almost all kinds of user needs like the experimentation, modifications and options. These inferences were derived from primary and secondary research. The app creates a basic user profile and has a cloud library that saves images and videos of the prints.

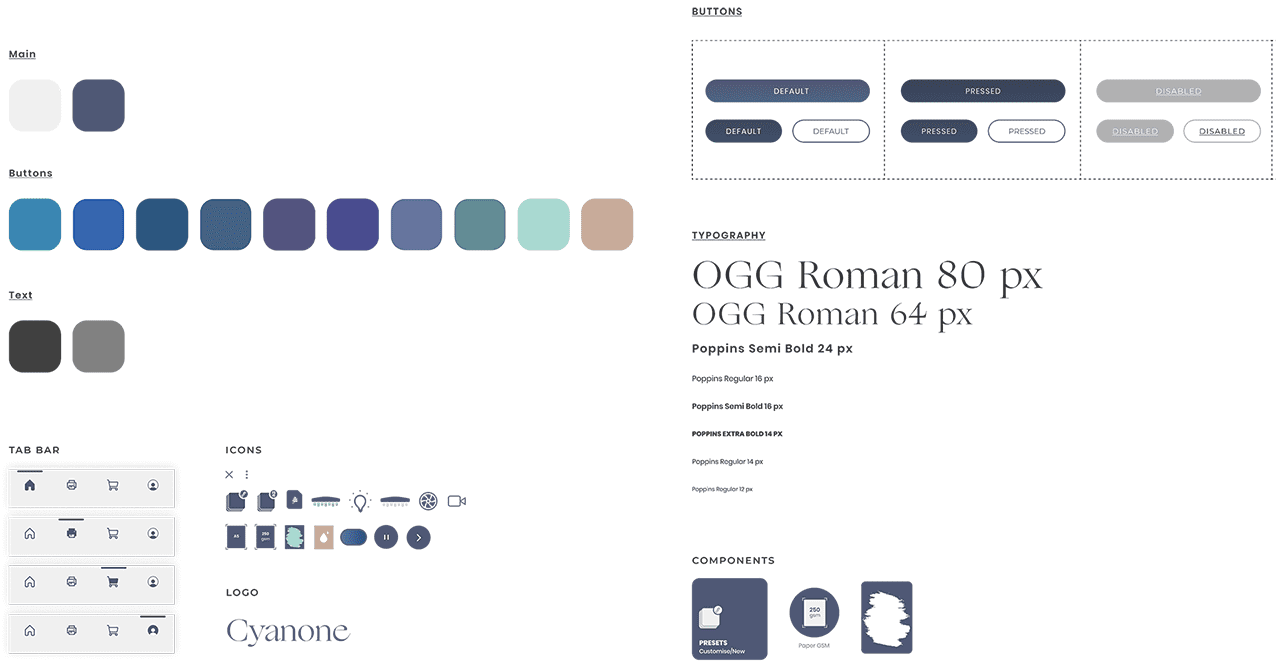

Design System

Inspired from cyanotype print colours and sophisticated minimal fonts that keep the process easy and motivate users to interact with it efficiently.